NANO MEMBRANE FILTRATION

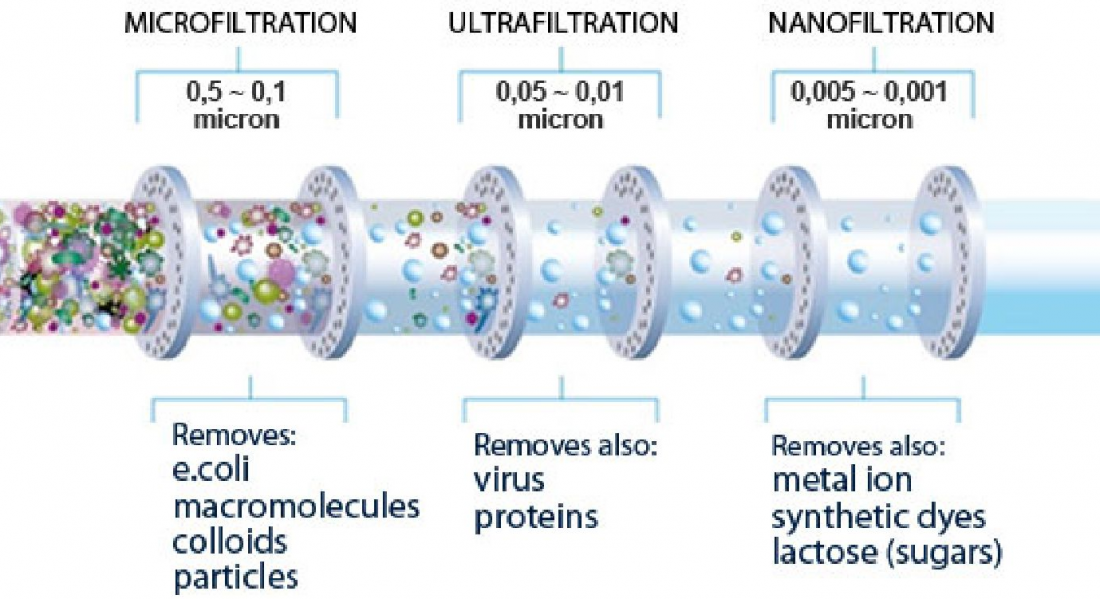

Nano-filtration is a membrane filtration-based method similar to Reverse Osmosis, that uses high pressure and nano-meter sized pores, to separate liquid with dissolved solids into two streams. The membranes have pore sizes ranging from 1-10 nano-meters, smaller than that used in micro-filtration and ultra-filtration, but just larger than that in Reverse Osmosis.

Nano Membrane Filtration Vs Reverse Osmosis

Reverse Osmosis is more associated with the production of pure water, and with sea water Desalination, where the removal of Sodium and Chloride Ions is required.

This method uses a larger pore size that allows Sodium and Chloride Ions to pass through, but rejects most of the larger multi-valent Ions such as Calcium and Magnesium. They also reject larger organic molecules such as sugars, proteins, Bacteria and Virus’.

Separation Using Nano Membrane Filtration

Many separation processes do not operate at room temperature (e.g. distillation), which greatly increases the cost of the process when continuous heating or cooling is applied. Performing gentle molecular separation is linked with nano-filtration that is often not included with other forms of separation processes (centrifugation). These are two of the main benefits that are associated with nano-filtration.

Nano Membrane Filtration has a very favorable benefit of being able to process large volumes and continuously produce streams of products. Still, Nano-filtration is the least used membrane filtration method in industry, as the membrane pore sizes are limited to only a few nano-meters. For anything smaller, Reverse Osmosis is used and anything larger requires ultra-filtration.

Ultra-filtration can also be used in cases where nano-filtration can be used, due to it being more conventional. A main disadvantage associated with nanotechnology, as with all membrane filter technology, is the cost and maintenance of the membranes used.

To find out more about our nano membrane filtration services, please get in contact today.

Nano-Filtration can be used as an alternative to Salt based Ion Exchange water softeners, due to their rejection of Calcium and Magnesium Ions.

Hardness levels are greatly reduced, but residual hardness is much greater than a conventional water softener. For some processes, this hardness can prevent corrosion problems associated with fully softened water.

Initial costs for Nano separation is much greater than water softening, however the lack of Salt for regeneration and subsequent high Chloride waste can make this an attractive proposition.

Food industry applications are numerous. In the dairy sector, Nano-filtraton is used to concentrate whey, and permeates from other whey treatments, and in the recycle of clean-in-place solutions.

In the processing of sugar, dextrose syrup and thin sugar juice are concentrated by Nano-filtration, while ion exchange brines are demineralised.

Nano-filtration is used for the degumming of solutions in the edible oil processing sector, for continuous cheese production, and in the production of alternative sweeteners.