Cooling Tower Water Treatment

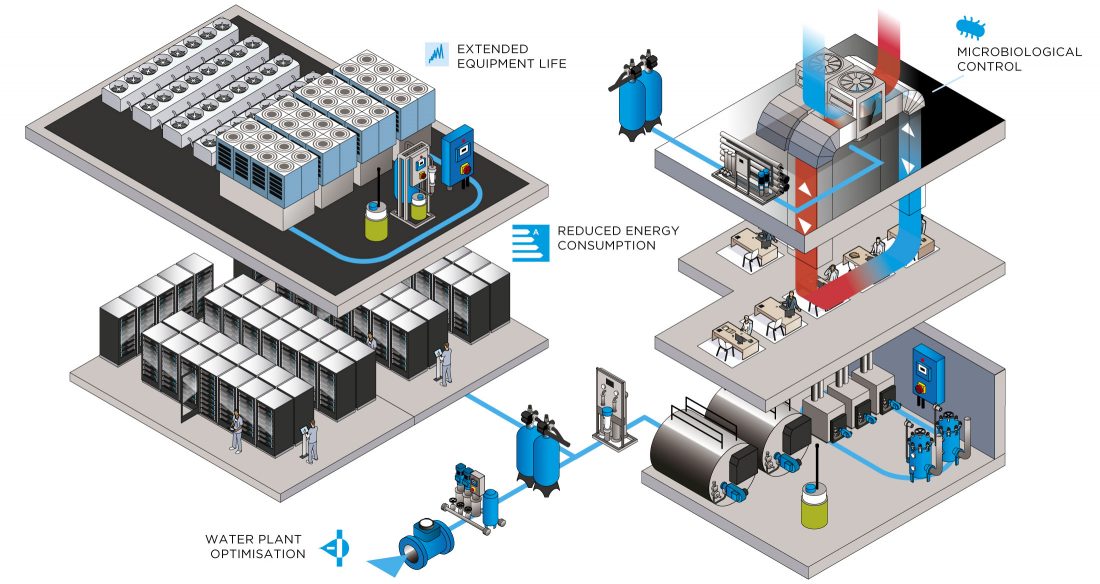

At Lubron, we provide cooling tower water treatment services that are tailored to the specific needs of our clients. We’ve been a trusted name in the industry for many years, renowned for our cutting-edge solutions that improve efficiency, extend equipment lifespan, and promote sustainability. We can address issues such as scale formation, corrosion, and microbiological growth within your cooling tower system, using advanced technologies and techniques to ensure exceptional results.

Why is cooling tower water treatment so important?

Cooling towers are commonly used in industrial facilities to disperse the heat created during various processes. The water inside these cooling towers is exposed to the atmosphere, which means it can be easily contaminated with scale, corrosion, and microbial growth. This untreated water can lead to a range of issues, including reduced heat exchange efficiency, increased energy use, and equipment damage.

As a result, cooling tower water treatment is performed, with various chemical, physical, and biological processes used to mitigate these risks. The aim is to maintain water quality by preventing scaling, corrosion, and microbial growth, and improve the overall efficiency and longevity of the cooling tower system.

What do cooling tower water treatment services involve?

As one of the leading cooling tower water treatment companies in the UK, we provide a range of services to address various challenges associated with industrial cooling systems:

- Water analysis. We’ll start by carrying out a detailed water analysis. This involves us conducting a comprehensive assessment to identify specific issues such as scale formation, corrosion, and microbial contamination. This analysis allows us to develop an effective treatment program for your cooling tower system.

- Tailored treatment programs. We will design a tailored treatment program that’s based on the unique requirements of your cooling tower. We’ll consider factors like water quality, the system specifications, and what industrial processes are used, ensuring we deliver the most effective solutions. Whether you need cooling tower blowdown water treatment, or any other service customised to the specific needs of your system, we can assist.

- Cutting-edge technologies. At Lubron, we use a range of cutting-edge technologies to treat the water in cooling towers, helping to prevent scale formation, corrosion, and microbial contamination. We use carefully selected cooling tower water treatment chemicals which are applied in precise amounts to ensure optimal performance as well as compliance with the latest industry standards. As well as using chemical processes, we use a range of physical treatments such as advanced filtration and water softening techniques.

- Regular monitoring and adjustments. A key part of our cooling tower water treatment services is the regular monitoring of your system. Once the initial treatment has been carried out, our skilled technicians will monitor it regularly, making any necessary adjustments to ensure the treatment remains effective over time.

To hire us to provide cooling tower water treatment services, get in touch with our team today. Phone us on 01206 866444 or send an email to sales@lubron.co.uk. We’re on hand to discuss your water treatment requirements in detail.

FAQ’S about cooling tower water treatment

Why do we add chemicals to a cooling tower or cooling system?

The recirculating water is the perfect environment to produce scale, sludge and microbiological activity including the production of Legionella Pneumophila. The correct management programme and application of cooling tower water treatment chemicals will control and eliminate these issues.

Why is the number of concentration cycles important in cooling towers and cooling systems?

Higher concentration cycles will reduce the volume of water used or bleed down the drain and hence water costs, discharge costs and the environmental impact should be considered at all times. However, high cycles enhance the need for the right chemical programme to be put in place, including cooling tower scale inhibitor and biocide dosage along with testing of water quality at all times.

Is legionella control really an issue?

Yes, it is a number one priority in cooling tower systems as they are the perfect environment in encouraging population growth of Legionella organisms. The transfer of these organisms in aerosols can be inhaled by anyone in their local environment. The complete chemical management and correct testing and cleaning programme is required at all times.

Who requires training in legionella management?

Any person who is involved in the operation and management of cooling towers and systems must receive training. This covers the engineer on the ground to the senior management team as required by all current Legionella Health and Safety legislation.

OUR SERVICES FOR COOLING AND BOILER WATER TREATMENT

Advice and support for water modification

As a partner of many installers, suppliers and consultants Lubron provides customised water treatment systems for various industries, including food and beverage, textile, chemical, pharmaceutical, electronics, glazing and construction. Lubron considers the quality requirements for the final product and its specific application tailoring, our advice and consultancy to create a unique solution.

Design and assembly

When designing a process water system, Lubron takes into account all aspects of end use such as: quality requirements, applicable laws and regulations, energy efficiency, maintenance and operating costs. Every installation is professionally designed and manufactured to Lubron’s leading European standards.

Commissioning and maintenance

As a whole project partner, following installation, Lubron takes care of the complete commissioning process, including training on operation and maintenance. Our industry-leading maintenance service supports operations and enhances the life of your investment. Should you experience any problems, you have the assurance of support day or night from our 24/7 response team.